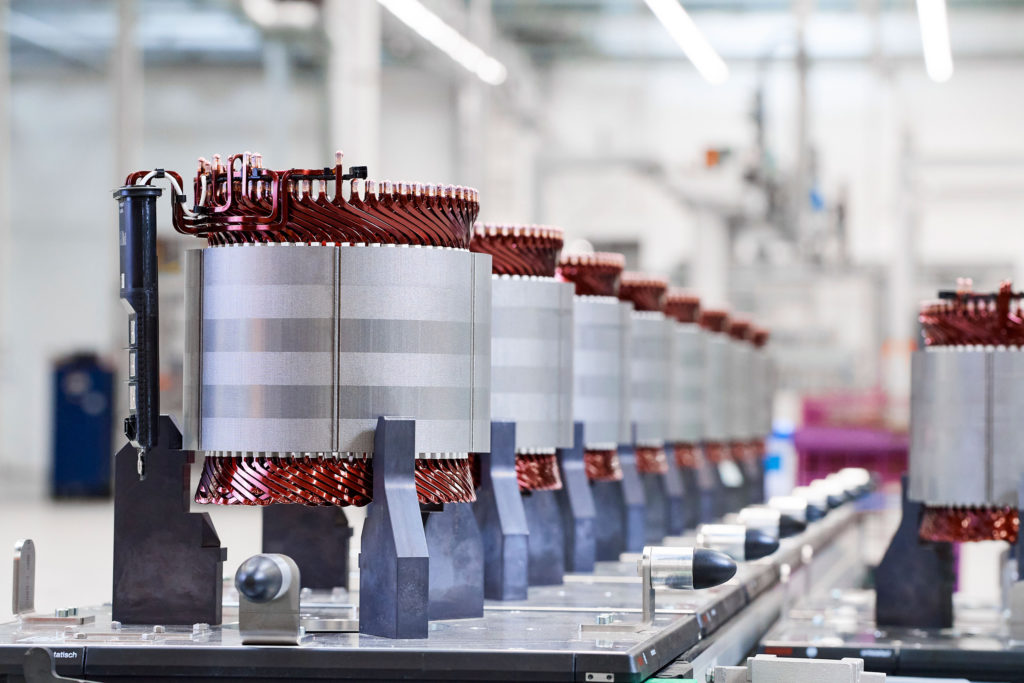

It doesn’t receive the same attention as cobalt, lithium, manganese or rare-earth metals, but copper is still an indispensable and highly valuable material that’s absolutely critical to our modern world. Through BMW i Ventures, its venture capital fund, BMW announced on Thursday that it’s taken a stake a Colorado-based company called Jetti Resources that is developing new ways of obtaining copper from waste materials. This metal is not only critically important to producing electric vehicles, but maintaining and expanding the energy grids of entire nations as well.

MUST SEE: 2023 Toyota Grand Highlander SUV teased, should offer Hybrid Max powertrain

Jetti Resources has figured out how to extract this reddish-hued metal from unused ore leftover from existing mining operations. The company has developed a catalytic leaching process that allows them to extract copper from ores that have, to date, gone unexploited. According to BMW’s media release, “Around 70 percent of the world’s copper resources are bound up in those primary sulfide ores. Material, previously stored in dumps and considered waste, can now be tapped into with this new form of resource-conserving extraction.”

Jetti Resources’ technology can increase the lifespan of existing copper-producing facilities, making the mining process more sustainable and less damaging to the environment. Treating the ores to a catalytic process that includes heap and stockpile leaching results in 40% fewer emissions compared to conventional copper-extraction processes and only requires about half the water.

In simple terms, the process works like this: A dilute acid is dripped through piles of low-grade copper ore. The environment this creates allows special microbes – specifically lithotrophs and ferroxidants – to break down and oxidize the ore via natural processes, which results in a copper-rich solution that can later be processed. Jetti Resources’ unique technology also works on primary sulfide ores, which have an inhibitory passivation layer that forms and prevents effective leaching.

This process allows commercial quantities of copper to be produced from low-grade source material, ores that, according to Jetti Resources, contain “70% of the world’s remaining copper resources.” Until now, these materials could not be processed in an economically viable way. The company’s technology is already successful and being used at an industrial scale. They plan to expand their global operations in cooperation with other partners.

In the same press release, Wolfgang Obermaier, head of indirect goods and services, raw materials, production partners of the BMW Group said, “By investing in Jetti, we are supporting technological progress in the field of copper extraction, with a focus on responsible and resource-conserving methods.” He added, “This new process has the potential to improve the environmental footprint and integrity of our supply chain, even with growing demand for resources like copper.”

SEE ALSO: Lectron Tesla to J1772 charging adapter hands-on review

Protecting supply chains will be absolutely critical in the coming years. As automaker bet the proverbial farm on electric vehicles, demand for materials like cobalt, lithium, manganese and nickel will only continue to grow. Many of these metals are in short supply today, but with BMW’s investment in Jetti Resources, perhaps copper will no longer be as expensive and hard to come by as it is right now.